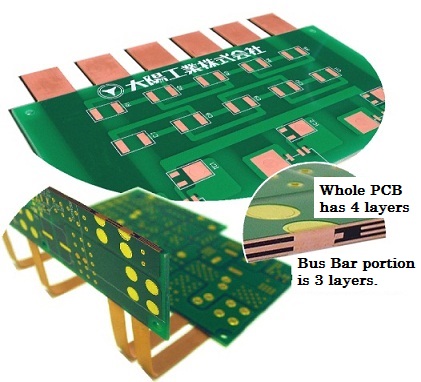

Bus Bar Embedded PCB

Conventional High Current handling PCB was expensive because thick copper was used on entire board, and cost of copper is increasing. However, we can reduce cost of such PCB by changing to Bus Bar Embedded PCB. And it becomes possible to assemble parts on bus bar by combining bus bar and PCB. Furthermore, you can get more effective heat dissipation by combining Copper Inlay.

Advantages of Bus Bar Embedded PCB

- PCB with a built-in ultra thick bus bar (500-2000µ)

- Choices for shape of Bus Bar are available.

- Regular parts mount is possible with Bus Bar Embedded PCB.

- Bus Bar Embedded PCB also can obtain countermeasures for heat combining with Copper Inlay.

- Bus Bar Embedded PCB can solve various problems occurring from High Current/High Heat.

- Possible to place connectors at the edge of PCB from inside PCB layers (You can choose the connector layer from internal layer or external layer.)

- External cable wire connections can be replaced by built-in wiring connections on PCB, this PCB can reduce number of parts and improving connection reliability.

Specifications

Number of layers :2-6 layers

Board Thickness :1.3-3.5mm

Copper Foil Thickness :External layer) 300/400/500µm

Internal layer) 18/35/70/105/140/175/210/240/300/400/500µm

Others :UL listing is completed. →Click here for UL certification.

Copper Inlay :Available

Usage

- Replacement of Bus Bar

- Others

- | Top Page |

- Company Profile |

- Contact |

- Privacy Policy |

- | High Current |

- Heat Dissipation |

- Design Team |

- Locations |

| All rights reserved, Copyright 2007(c)TAIYO KOGYO.CO.,LTD. |